Mecàniques Taradell

Specialized in the construction of machinery and components according to customer design.

It is a company founded in 1966 that is dedicated to the construction of machinery and the mechanization of parts. We have modern facilities, since in July 2018 the expansion works began where we went from working in a 1600m2 warehouse to one of 3200m2. This allows us to manufacture machinery of considerable dimensions.

We are specialized in the construction of machinery and components according to customer design in short, medium series and prototypes for different sectors: metallurgical, wood, renewable, aeronautical, automotive, printing, packaging, food, etc.

Our organization and our scope of action in continuous growth, together with the needs of our clients, make us a company open to the future and with the capacity to face new challenges. Our machinery allows us to achieve a high volume of production and offer our customers a high level of quality.

We have specialized machinery for machining work on parts up to 4 m in length, boilermaking and paint finishes.

FACILITIES

Welding and boilermaking

We have a large welding section as well as a team of certified welders.

Equipped with ESSAB pulsed arc welders, continuous welding equipment and a Panasonic welding robot.

Complemented for all the necessary works, with a plasma, a 2-meter folding machine, a 100-ton vertical hydraulic press, threading machines, among other equipment.

Machining

Our variety of machines, added to our team, with years of experience in the sector, allows us to carry out a wide variety of machining.

We have two Soraluce machines, one with a 3.5-meter bed and the other with 2.5 meters, all of them with a rotating head.

A DMG MORI five-axis machine, as well as another machine from the same brand with a 2.2-meter bed and rotating head.

We also have a turn of the Okuma brand, with 3 axes and a motorized turret. And up to six other 3-axis machining controls of various sizes, some of them equipped with 4th axis, measurement probes and built-in automatic tool setters.

Assembly of machines

We have a specialized team with experience in machine assembly.

In addition to a part of the facilities dedicated only for them, equipped with overhead cranes of up to 10 tons, which allow us to satisfy the needs of our customers, from small assemblies to large machines.

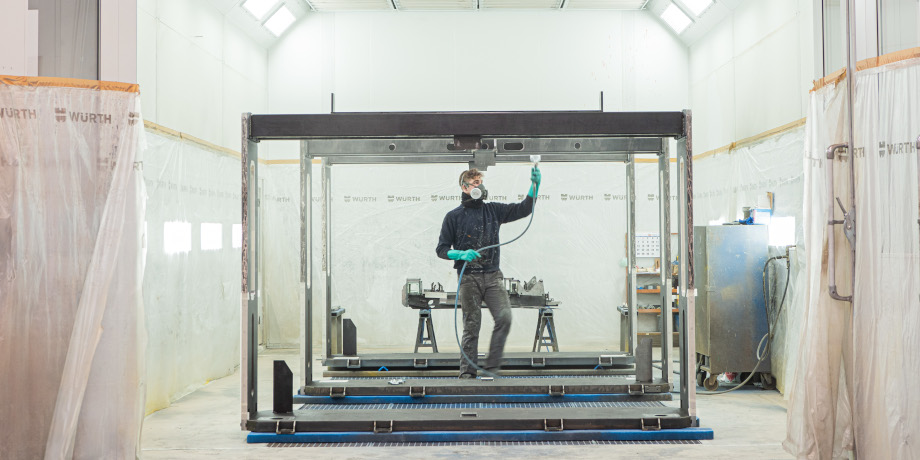

Paint

We have two paint booths. All of them equipped to be accessible with overhead crane and capacity for parts or machines up to 8 meters long.

In addition, we also have cleaning systems both in ice and in pressurized water from the Karcher brand.

This allows us to give the customer a fully finished part service.

Cutting

We have a cutting section equipped with two automatic saws and two CNC saws.

In addition to an automated warehouse for storing raw materials for bars over 6 meters long.

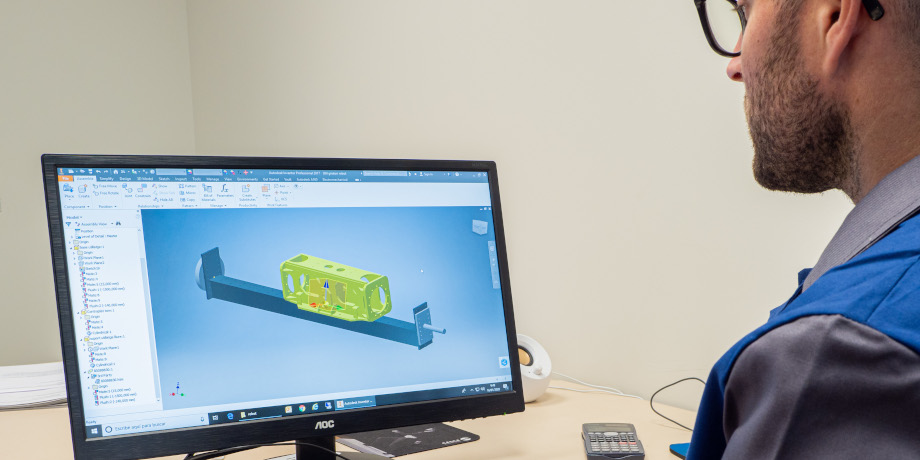

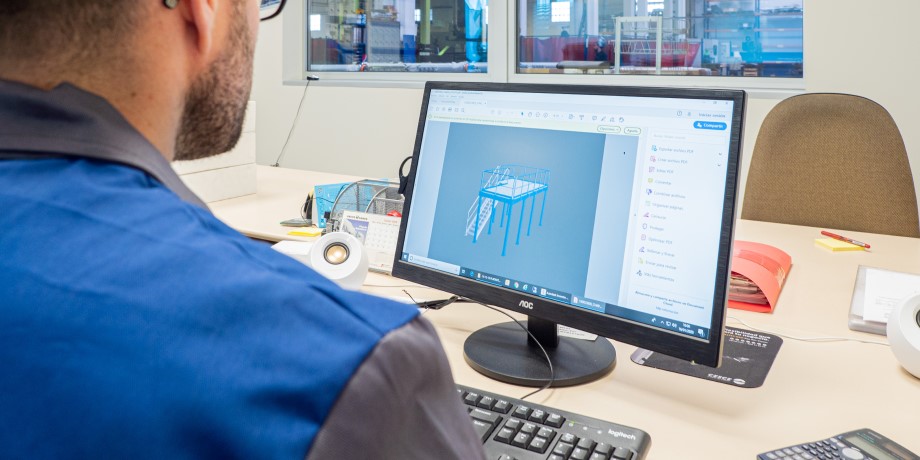

Technical office

In our technical office we have qualified personnel for CAD/CAM programming, through the Mastercam program.